Component Digitization

In product design and engineering, details make the difference. One of the most critical—and often underestimated—steps is the digitization of every component that will be part of the assembly. Having each piece modeled in 3D, from PCBs to the smallest custom screw, allows you to spot issues before manufacturing, cut costs, and speed up development.

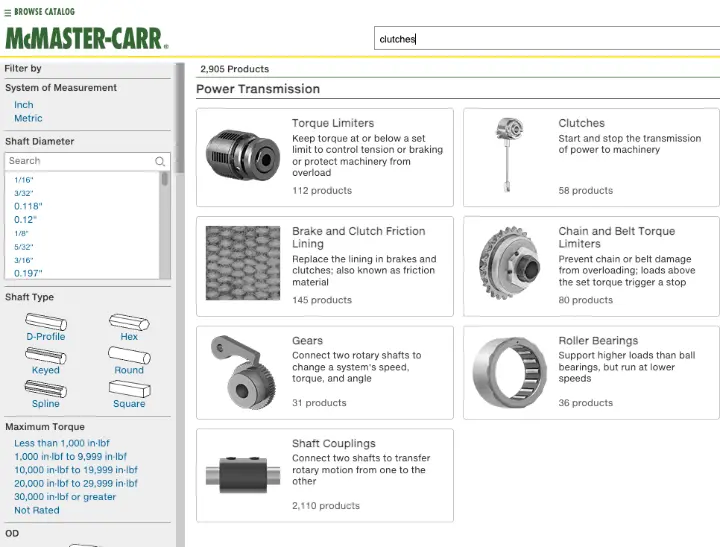

Today, we have extraordinary resources: many suppliers provide complete catalogs of ready-to-download digital parts. Integrating them into your design not only saves time but also ensures accuracy. Some key sources include:

- McMaster Carr: perhaps the most complete catalog of fasteners and mechanical components, with impeccable specifications.

- TraceParts: a library with thousands of electronic and mechanical industry components.

- SDP-SI: a go-to resource for gears, pulleys, and shafts.

But what happens when the component you need is not digitized? That’s where the community comes in. Platforms like GrabCAD host thousands of models shared by engineers and designers around the world. Other repositories like Sketchfab, Thingiverse, or TurboSquid also exist, though some are more suitable for quick prototypes or visualization than for precision engineering.

from my grabCAD profile

What Should Be Digitized?

To ensure a functional and manufacturable design, I always recommend digitizing:

- PCBs and internal electronic components: chips, resistors, capacitors. This prevents collisions and ensures correct height and form factor.

- Antennas, sensors, and displays: many need to protrude from the product or provide visible interfaces.

- Labels, signals, and markings: they add realism and help identify orientations, rotations, or warning points.

- Cables, hoses, and connectors: planning for bending and movement space avoids costly redesigns.

- Special fasteners: even if available in catalogs, modeling unique parts guarantees assembly precision.

Why Is This Step So Important?

Because a complete digital model of the product prevents design errors that would otherwise surface only in later stages—when correction costs are much higher. Digitization also improves team communication, generates more realistic renders, and enables validation of assemblies with simulation tools.

Conclusion

In my projects, I’ve seen how component digitization transforms the process: teams detect issues earlier, physical testing becomes more efficient, and time-to-market is reduced.

Whether you’re looking for an external engineering team to develop your product, or seeking a professional with experience in transportation, electronics, and manufacturing design, this approach is part of what I bring to every project.

I bring hands-on experience in product development, electronic and mechanical integration, manufacturing, and project management.

Let’s talk about how my expertise can bring value to your team and accelerate your innovation projects.