Designing Products That Survive the Streets: Lifecycle Planning for Public Transport Tech

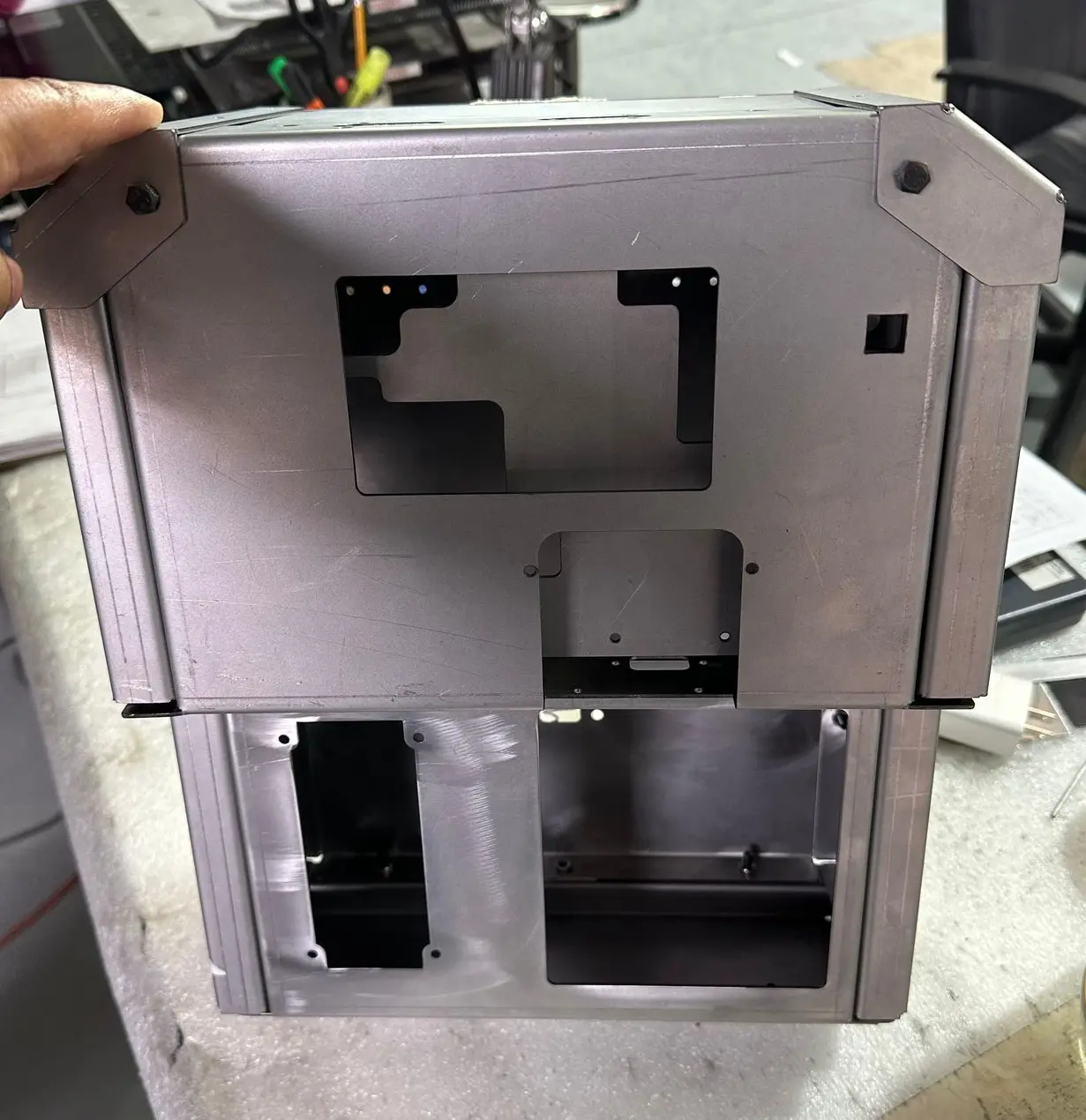

When we think about public transport, we usually picture passengers, routes, or vehicles. But behind every prepaid card validator, ticket machine, passenger counter, or display screen, there is hardware that must work reliably for years in harsh environments.

Designing this type of product is not the same as designing a consumer gadget. Here, lifecycle planning and product variant management are essential.

1. Understand the Real Environment

Public transport hardware faces:

- Constant vibrations. As a mechanical engineer, I know how damaging they can be to any product.

- Extreme temperature changes, sometimes with swings of dozens of degrees Fahrenheit.

- Dust, humidity, and vandalism. Designers must assume that every small hole will eventually be filled with dirt or trash.

- Heavy usage cycles, often thousands of times per day, with minimal maintenance.

That’s why materials, assemblies, and electronics must be chosen for resilience—not just for cost. These products are part public equipment, part industrial machine, and part user-friendly device.

2. Design for Installation and Maintenance

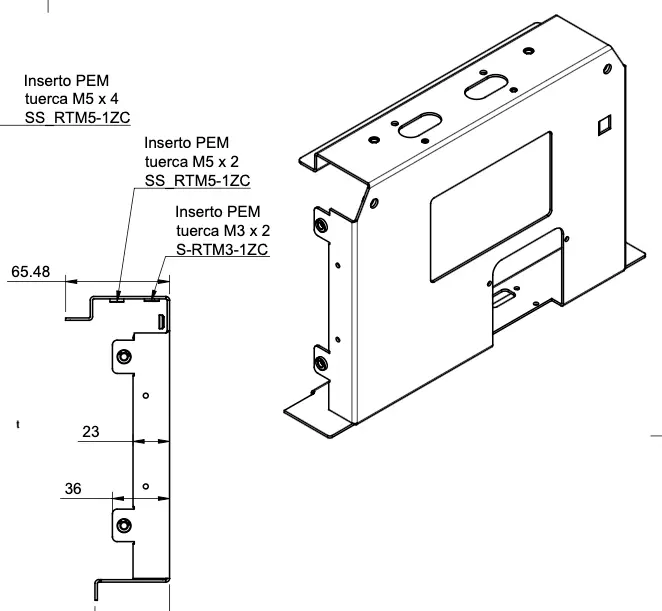

Every product must be designed considering installation in different types of vehicles, often with custom modifications and non-standard conditions. A creative approach is key.

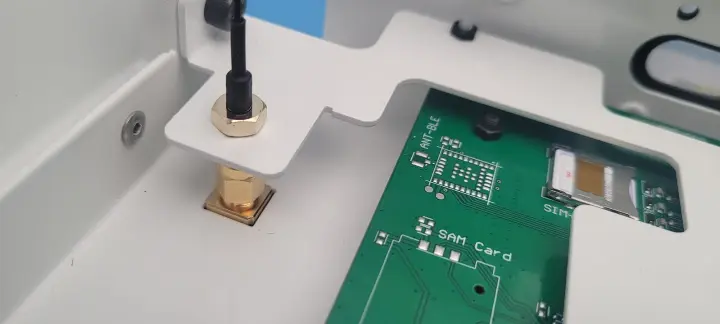

Street hardware cannot be easily discarded. Designing with replaceable modules (for example, a communication board that can be swapped without dismantling the whole device) reduces operational costs and extends product life.

3. Component Standardization

Using standardized screws, connectors, and materials simplifies inventory, improves logistics, and speeds up field repairs. This is part of thinking about the full lifecycle from day one.

As I described in another post, choosing the right screws can prevent countless headaches and simplify the entire design

4. Simulation and Testing from the Start

Designing for durability doesn’t mean waiting until the final prototype. Tools like Fusion 360 allow us to simulate stresses, vibrations, and thermal cycles, while accelerated testing methodologies validate assumptions before production.

I always tell my clients: products are never designed in one shot. Iterations, prototypes, and multiple test rounds are essential—not only to validate the design itself but also suppliers, logistics, and your Bill of Materials.

5. Integration with Operations Management

This is where an ERP like Odoo comes in. With it, we can:

- Manage versions of each designed or purchased part.

- Track spare parts and inventory, both internal and with suppliers.

- Record manufacturing costs, engineering changes (ECOs), and maintenance.

- Plan component replacements in scheduled cycles—using data collection and analysis to make accurate predictions.

In this way, design doesn’t stop at CAD: it connects directly with real-world operations.

Conclusion

A product designed for public transport must do more than perform its initial function: it must survive time, environment, and intensive use. Thinking in terms of the full lifecycle is what separates a promising prototype from a system that truly supports the city, day after day.

If your team is building hardware for public transport—or any product that needs to survive in tough environments—let’s connect. I’d love to share my experience designing resilient systems that bridge engineering and operations.