Most people associate product management with software, but managing hardware products is something entirely different.

Hardware teams face the challenge of coordinating at least three separate engineering disciplines:

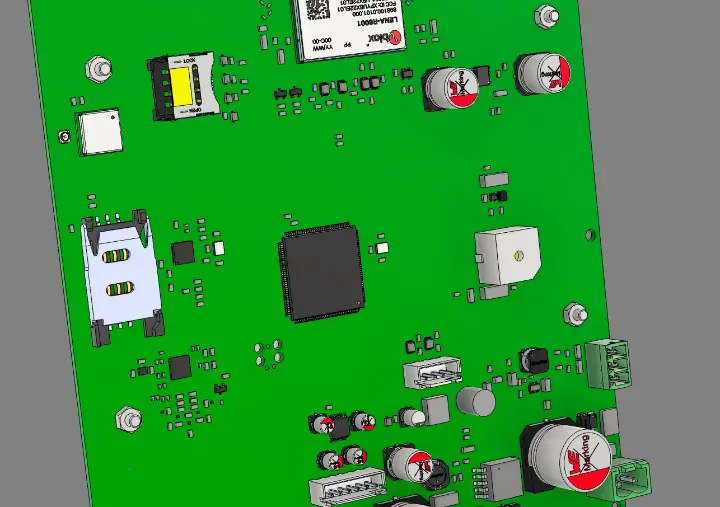

- Hardware Engineering – PCB design: the Brain and Nervous System of the product.

- Firmware Development – Embedded code: the Soul and Mind of the product.

- Product Design – The physical form: the Body and Muscles of the product, which includes enclosures, mechanisms, and materials (plastic, metal, textiles—or all together, as in wearables).

This setup is already complex by nature, requiring specific design philosophies and workflows. But beyond engineering, hardware product teams must also manage:

- Suppliers and long lead times

- Dozens of prototypes with vastly different iterations

- The design and manufacture of custom testing tools

- Mechanical failures

- Logistics of physical components

- And many unpredictable variables

Now add:

Delivery deadlines, marketing constraints, financial targets, and regulatory requirements…

And you’ve got a hands-on MBA in operations.

If you haven’t brought a hardware product from idea to first production run—you don’t know the half of it.

After more than 10 years managing hardware projects in sectors like public transport, medical devices, and agri-IoT, here are the key lessons I’ve learned:

1. Your Bill of Materials (BOM) is your single source of truth.

Treat it like code. Manage it with strict version control.

(The topic of BOM versioning alone deserves its own post—coming soon.)

2. Suppliers are part of your team.

Keep them close. Communicate often. Hold regular reviews and check-ins.

Pro tip: Always have at least two supplier options for every critical component.

3. Use modern tools that support agile thinking.

Odoo, Jira, Asana, Monday, Notion—even Google Forms with automation—can make a massive difference.

Trying to run a hardware development operation entirely on Excel is a one-way ticket to failure.

4. Assume every plan will change.

Your job is to adapt, not to resist. Experienced PMs know this: plans are flexible, goals are not.

Change is constant—adaptation is key.

5. Design with testing in mind.

Golden units and test protocols can save entire product lines. Every component or subsystem must have its own test plan.

6. Document everything.

Nobody loves it, but it’s essential. Documentation is the unglamorous hero of every successful project.

As a data analyst, I document everything—including internal meetings.

I've even created my own method for efficient documentation (coming in a future blog post).

Managing hardware development isn't just about deadlines.

It's about managing uncertainty—with structure.

Want to go deeper or talk about your next project?

Connect on LinkedIn or reach out at Dagaa.co