An ERP is needed

Most hardware teams face the same problem: what is designed in engineering rarely flows smoothly into production, procurement, and operations. The result is usually chaos, delays, and extra costs. Why? Because each department works in its own “island” of information: spreadsheets, emails, CAD software, and outdated bills of materials (BOMs).

In my previous experience as Product Head at a tech startup developing an assistive device for the blind, I led four engineering teams:

- Hardware

- Firmware

- Mechanical Design

- Quality Assurance & Compliance

We faced these problems many times. Version control chaos for each part, undocumented engineering changes (ECOs), outdated BOMs, and especially the challenge of requesting manufacturing quotes or component purchases from suppliers across different companies, cities, and countries.

Another part of the problem was the rest of the startup’s departments: Procurement and Finance. They tried to manage everything with Excel sheets and a good task manager like Monday. But as an ERP, it didn’t work. Information was duplicated or lost, and sometimes material was purchased incorrectly, which of course caused conflicts, stress, and unnecessary spending.

With those experiences in mind, at Dagaa we found that Odoo ERP works as the missing link between design and operations, allowing hardware teams to integrate the flow from engineering all the way to final delivery. Most importantly, it brings version control beyond CAD—something other tools don’t handle outside design environments.

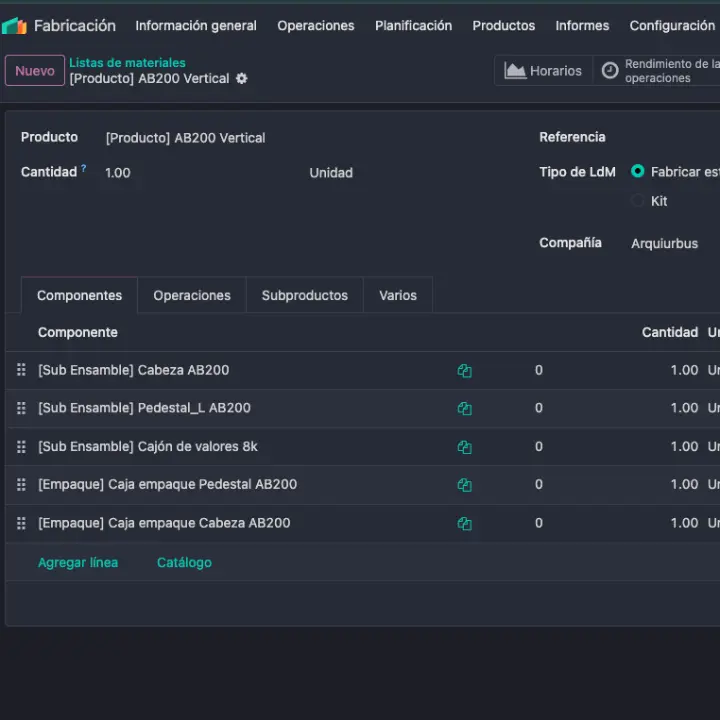

1. From CAD to a Living Bill of Materials (BOM)

One of the biggest challenges in hardware is keeping the bill of materials updated. With Odoo:

- BOMs can be imported or synced directly from CAD or PCB design tools.

- Every change is recorded and updated in real time.

- Operations and procurement always work with the latest version, without duplicating efforts.

Configuring your database properly is key, and while that has its own challenges, once you understand the flow in Odoo it becomes straightforward.

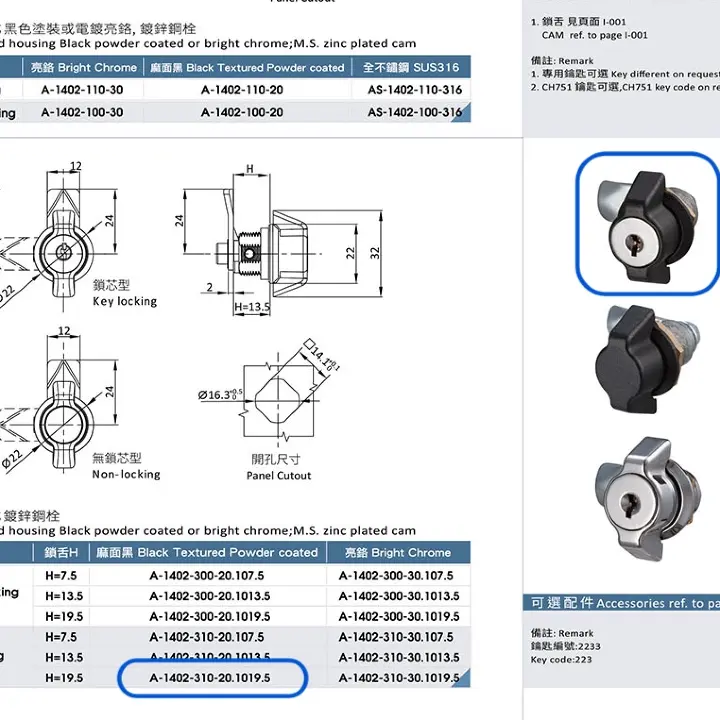

2. Purchasing and Suppliers in One Place

Instead of endless email chains, Odoo connects engineering with procurement:

- RFQs are generated automatically from the BOM.

- A history of suppliers, prices, and lead times is tracked.

- Errors are avoided when ordering obsolete parts or components from outdated versions.

- Engineering teams can easily create RFQs themselves, attaching drawings and specs. Then, purchase approvals can be set up by team leads to align with budgets and control costs.

3. Smooth Production and Inventory Control

The transition from prototype to pilot production is where the biggest problems usually appear. With Odoo:

- Inventory updates automatically as materials move in and out.

- Manufacturing teams receive clear work orders based on current versions.

- Pilot runs can be planned and easily scaled to larger batches without redoing processes.

- Product variants (sizes, colors, models) can be configured efficiently.

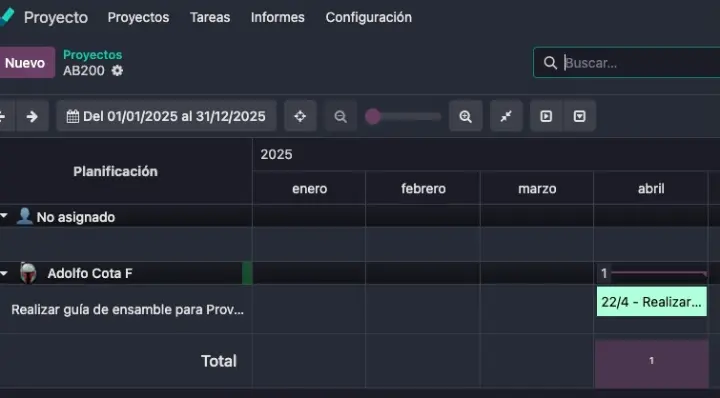

4. Project Management and Transparent Communication

Beyond materials, Odoo integrates project management tools:

- Tasks assigned with clear accountability. I’ve used Monday, Jira, Notion, and Asana, but I prefer Odoo because it integrates with modules for time, cost, and operations.

- Gantt and Kanban views to visualize progress. As an Agile project manager using Scrum and Kanban, I find Odoo fits perfectly with my workflows.

- Centralized communication in one place, eliminating scattered chats and emails. This does require training so that people stop relying on WhatsApp or SMS and instead use Odoo—but once the benefits are clear, everything flows better. I also recommend using Slack for team communications, which integrates nicely with Odoo.

Conclusion

For hardware teams, Odoo is not just an ERP—it’s a translator between engineering and operations. It ensures ideas don’t get lost in the transition to production and helps every iteration be faster and more organized.

At Dagaa, we’ve applied this approach to reduce friction between teams, accelerate prototype validation, and most importantly, deliver market-ready products with less rework and fewer unnecessary costs.

Does your hardware team struggle with the transition from design to production? Let’s talk about how Odoo ERP can bring order and speed to your development.