Bringing a tech product to life involves far more than a great idea. From the earliest conceptual sketches to production-ready CAD files, every decision impacts cost, time-to-market, and product quality.

At dagaa, we’ve spent over a decade helping companies develop smart, manufacturable tech products. Our experience spans medical devices, public transportation payment systems, embedded electronics, and complex electromechanical systems. And across all of these, one factor stands out:

One of the most critical — and often underestimated — elements of success is Design for Manufacturability (DFM).

What is DFM, and Why Does it Matter?

Design for Manufacturability (DFM) is a product development approach that prioritizes how a product will be manufactured — not just how it functions. It accounts for real-world limitations like materials, tolerances, production processes, cost structures, and supplier capabilities.

According to Ulrich and Eppinger, two of the most cited authors in product development, DFM is built on key principles:

- Consider manufacturing constraints from the earliest stages — not as an afterthought

- Foster cross-functional collaboration between design, quality, manufacturing, and procurement

- Simplify components and assemblies to reduce part count and failure risks

- Select scalable and cost-effective materials and production processes

- Standardize technical documentation to avoid ambiguity during production

In short, DFM isn’t just a phase — it’s a design philosophy.

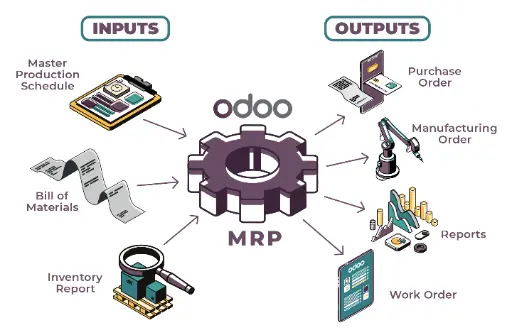

How Odoo Supercharges DFM

Many companies still operate with siloed information between engineering, procurement, and production. But with Odoo ERP, DFM becomes more than just theory — it becomes daily practice.

Here’s how Odoo turns DFM into action:

1. Design–to–Manufacturing Integration

Odoo bridges CAD/PLM and production. BOMs, drawings, and instructions flow automatically into manufacturing, ensuring that teams work with real, up-to-date specs aligned with actual capabilities.

2. Engineering Change Management (ECO)

Design updates automatically ripple across purchasing, inventory, and production. You can assess the real-time impact of any design change on costs, materials, and lead times before it’s implemented.

3. Cross-functional Collaboration

By centralizing information, Odoo enables true collaboration between engineering, manufacturing, quality, and procurement — leading to better decisions about materials, tolerances, and processes.

4. Simulation and Planning

You can simulate production orders before committing to them — validating plant constraints, lead times, and costs to fine-tune your designs based on real-world data, not assumptions.

5. Performance Feedback and Iteration

Quality, cost, and performance metrics can be directly tied back to design decisions, enabling continuous improvement across future product iterations.

Our Practical Framework for Designing Products Ready for Manufacturing

At dagaa, we apply DFM principles from day one. Here’s our field-tested approach:

-

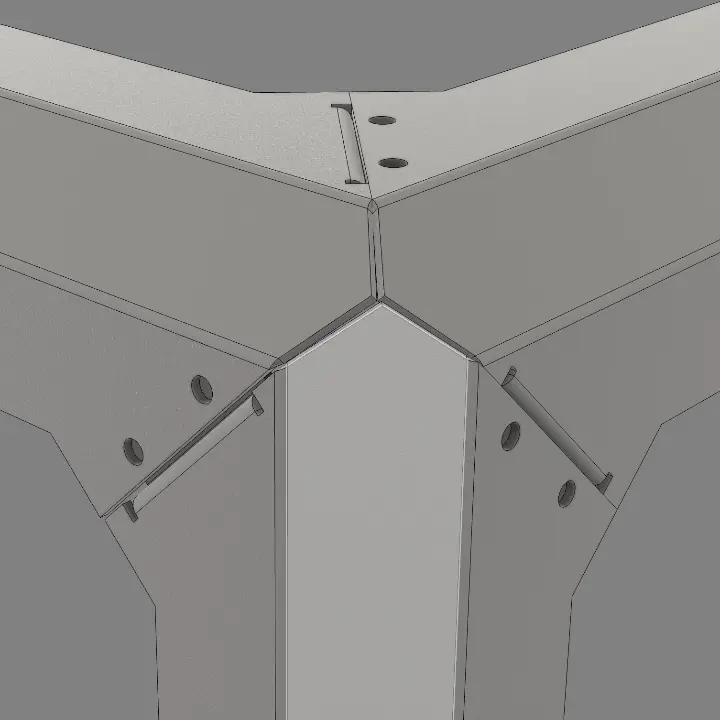

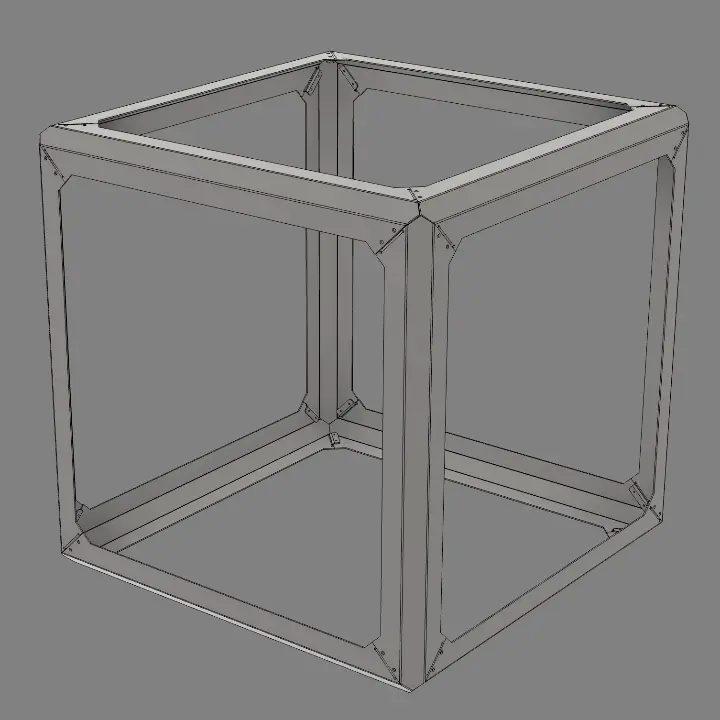

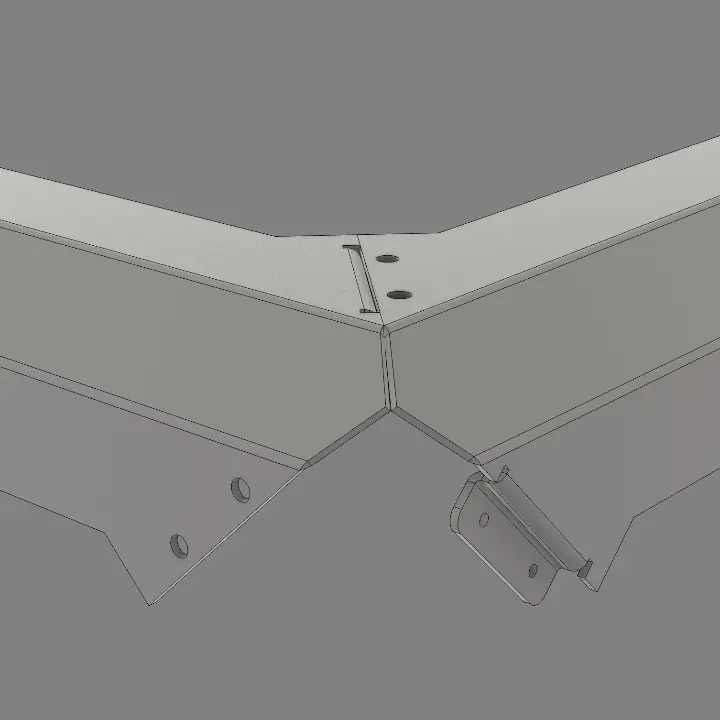

Start with Modularity

Think in subassemblies, not monoliths — this simplifies manufacturing, testing, and scaling. -

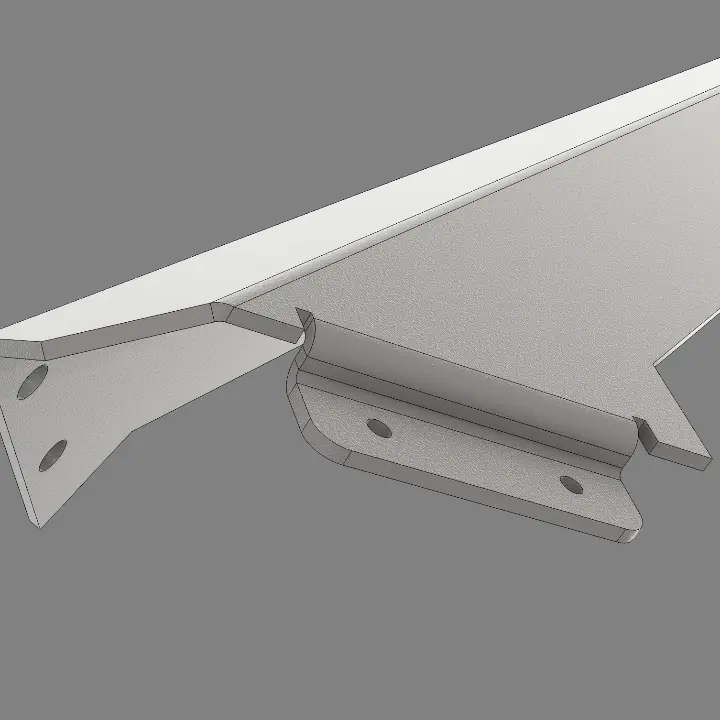

Design Around the Process

Is your product sheet metal, injection molded, or CNC machined? Every process comes with unique design rules. -

Plan Your BOM from Day One

Use tools like Odoo to connect your CAD files with sourcing and cost structures from the beginning. -

Prototype Early, Test Cheap

Use rapid prototyping to validate mechanical and assembly risks long before scaling. -

Document Everything for Smooth Handoff

Your suppliers will thank you for clear drawings, defined tolerances, and well-documented processes.

Bottom Line

Design doesn’t stop when your product looks good on screen. It ends when it can be manufactured reliably, repeatedly, and affordably.

Embracing DFM from the start — and integrating it into every stage of the product lifecycle with tools like Odoo ERP — is what separates attractive ideas from real-world success stories.

Curious about how to apply DFM in your next project?

Let’s talk. Visit us at www.dagaa.co or connect with me on LinkedIn to see how we can help take your product from CAD to market — with no surprises.