In recent years, more and more design firms and furniture manufacturers have started exploring finite element analysis (FEA) inside tools like Fusion 360 to “test” their designs before building them.

The promise is attractive: fewer prototypes, less waste, faster decisions.

But it’s important to be clear from the start:

- Simulation can be very helpful in furniture design, but it does not replace shop experience or physical prototyping, and it should not be seen as certified structural validation.

- When used with the right mindset, simulation becomes a powerful support tool for design and decision-making.

The Main Challenges of Simulating Furniture

Finite element simulation works best when certain conditions are met:

- Homogeneous and well-defined materials

- Clear geometries

- Predictable joints

- Well-known loads

In woodworking, reality looks different:

- Wood is a variable material, with grain, knots, and moisture differences

- Many joints are handcrafted (mortise and tenon, dowels, screws, glue)

- Hardware includes play and mechanical tolerances

- Real loads (people sitting, vibrations, daily use) are not always easy to define

In addition, tools like Fusion 360 usually model materials in simplified ways, often as isotropic, while real wood is highly anisotropic (its behavior changes significantly with grain direction).

Because of this, it is not realistic to expect a simulation to predict exactly where a joint will fail or the precise point where a wood component will break.

So What Can Be Analyzed with Real Value?

This is where simulation becomes truly useful for furniture workshops — when it is applied with the right goals.

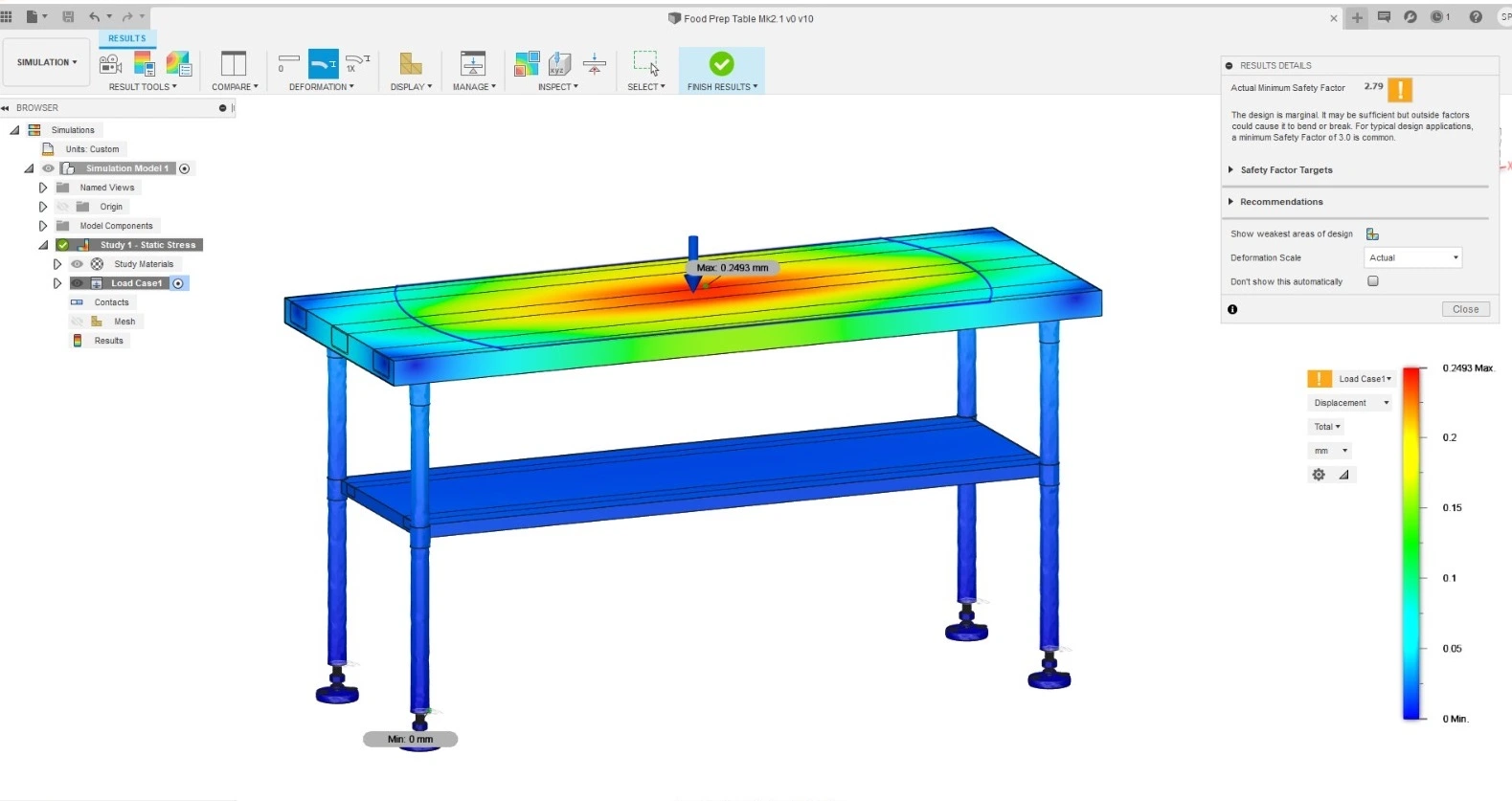

With Fusion 360, it is very feasible to analyze:

- Shelf and panel bending

- Deformation of tables, benches, and chairs under static loads

- Behavior of large panels

- Comparisons between different material thicknesses

- Comparisons between designs with and without reinforcements

This allows designers and manufacturers to answer very practical questions, such as:

- Will this shelf visibly sag over time?

- Is it better to increase thickness or add reinforcement?

- Which of these two geometries is stiffer using the same material?

Here, simulation is not used to “certify” the furniture, but to compare design alternatives before cutting wood.

The Real Business Value

From a business perspective, the biggest value is not perfect calculation accuracy, but:

- Fewer prototype iterations

- Reduced material waste

- Earlier detection of stiffness issues

- Better-informed design decisions

- Faster design → test → improve cycles

In shops where every prototype means time, materials, and labor, being able to discard weak design ideas on the computer before reaching the workbench has a direct impact on development cost and lead time.

Simulation does not replace the craft knowledge of designers and carpenters, but it sharpens that experience by making design trade-offs more visible and measurable.

Where Simulation Falls Short (and Why That’s Okay)

It is also important to be honest about limitations:

- It does not predict real joint failures

- It does not accurately model glue, screws, and friction

- It does not represent long-term behavior from humidity or fatigue

That is why physical prototypes remain essential, especially once a design is moving toward production.

But when simulation is used before prototyping, it helps teams reach that stage with more mature designs and fewer obvious risks.

From Design to Production: The Natural Next Step

This is where things become even more interesting for workshops that want to scale and professionalize their operations.

When design and simulation are connected with a manufacturing management system (ERP) like Odoo, it becomes possible to link:

- Design versions

- Bills of materials (BOMs)

- Real production costs

- Routing and shop-floor time

This opens the door to much more complete decision-making, where teams can evaluate not only whether a design is stiffer, but also:

- whether it is more expensive to build

- whether it requires more operations

- whether it affects shop capacity

In a future post, I’ll go deeper into how Odoo’s Manufacturing and Shop Floor modules can integrate with the design process so that technical decisions also become business decisions — not just engineering ones.

Because in the end, better design is not only about stronger furniture, but about more predictable and profitable operations.

How to Start Applying This in Your Shop

Every workshop is different: product types, materials, processes, volumes, and levels of standardization vary widely.

That’s why the real value of simulation and manufacturing systems is not in using the tools themselves, but in defining a workflow that actually fits daily operations.

At dagaa, we help manufacturers and workshops to:

- apply simulation in a practical way to their designs,

- define what is worth analyzing and what is not,

- and connect design decisions with real production processes using systems like Odoo.

If you are exploring how to reduce prototypes, improve design decisions, and gain better control over production costs and lead times, it’s worth having that conversation before investing in tools or training without a clear strategy.