Evolution with data

Not too long ago, product design was mainly based on assumptions, prior experience, and, in many cases, trial and error. While this approach enabled great innovations, it also involved long iteration cycles and high correction costs.

Today, the reality is different: data has become the most valuable raw material for designing, validating, and optimizing products. And with the incorporation of Machine Learning (ML), we don’t just interpret what happened; under the right conditions, we can predict and anticipate what will happen next.

In today’s tech industry, data is no longer a byproduct of design—it’s the fuel for its evolution. That is the key difference.

Use cases where ML makes the difference

The value of integrating Machine Learning into design is not theoretical; it translates into tangible improvements:

- Predictive maintenance in IoT devices: identifying failures before they occur, reducing downtime.

- Personalization in consumer electronics: adjusting the user experience in real time. This is particularly relevant, as in most of the projects I’ve been involved in, design is often guided by the desires, dreams, or so-called vision of the business owner or client, rather than real data. That’s why prototyping, testing, and refining through at least three iterations is critical.

- Demand forecasting for hardware products: aligning production with the market and avoiding excess inventory. This is the big dream of Operations executives—to guide purchasing, manufacturing, and inventory costs with data-driven decisions.

- Anomaly detection in manufacturing or sensor systems: reducing defects and quality costs. But detecting anomalies is not always negative—sometimes they can be the start of a new product, a new feature, or even a business opportunity.

Designing with data collection in mind

The biggest mistake I see in many projects is treating data as an “extra” rather than part of the design. Including sensors, usage logs, and performance metrics from the start allows the product to “speak” and the teams to constantly learn from it.

What I’ve seen, however, is that many business owners or decision-makers consider data only as a requirement for presenting to investors or boards—not as a critical element of the first commercial version. Usually, it’s only included from the second or third generation, which prevents faster, market-focused development cycles.

That’s why I believe in designing for observability. Every user interaction or system operation should become valuable information for improvement.

We are starting to see an evolution in product development teams, where a dedicated role (or at least one person) is responsible for collecting, analyzing, and transforming product data.

Previously, I have suggested the minimum team structure for developing hardware devices:

- Hardware

- Firmware

- Product Design

- Quality

To this list, I would now undoubtedly add: Data Analysis—from the very beginning.

Tools & infrastructure

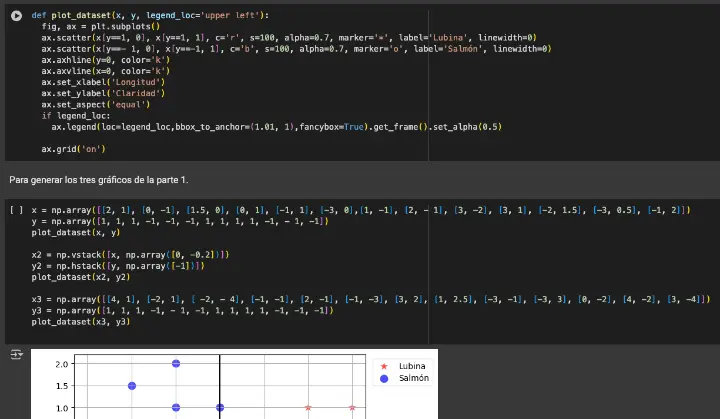

Today we have a mature ecosystem of technologies: Python, TensorFlow, AutoML, AWS SageMaker—all powerful for building models.

But what matters is not just the tool, but its integration with business management. This is where my experience with platforms like Odoo (IoT/PLM) becomes relevant, as they enable product data to connect directly with manufacturing, inventory, or after-sales processes.

When product design and ERP speak the same language, innovation doesn’t stay in the prototype—it makes an impact in the market.

Example from my experience

In a recent project, we integrated usage data collection into an electronic device. This allowed us to identify patterns that were invisible in lab testing and optimize the design before scaling production. The result: lower failure rates, reduced warranty costs, and higher user satisfaction.

On the other hand, I’ve also seen cases where data collection wasn’t planned. After launch, it became impossible to respond quickly to market issues. That confirmed what I now always repeat: what isn’t measured cannot be improved.

Challenges to consider

Integrating ML into design is not simple. Some key challenges are:

- Data quality (noise, bias, lack of context).

- Model drift: when models lose accuracy over time.

- Interpretability: models must not only be accurate but also understandable for teams.

- Cross-functional collaboration: engineers, data analysts, and business leaders must work together.

These challenges are real, but they can be overcome with strategic vision and technical leadership.

Conclusion

The future of product design lies in data and Machine Learning. Integrating them from the start accelerates innovation, reduces risks, and improves user experience.

Are you looking for a profile that combines product design, manufacturing, and applied data experience with a strong business vision?

I'm open to exploring opportunities where I can contribute my expertise to technology innovation projects.