Hardware Device Development

In the world of hardware design, success does not rely solely on a great idea or a functional prototype. A product that fails to meet safety and regulatory standards may face delays, unforeseen costs, and even market failure.

That’s why integrating Design for Manufacturing (DFM) with regulatory compliance from the very beginning is essential. These are not two separate processes, but a joint strategy to ensure that the product is manufacturable, safe, and validated from the earliest stages of design.

What Does It Mean to Integrate DFM with Compliance?

- DFM ensures that the product can be manufactured through efficient, repeatable, and cost-optimized processes.

- Compliance guarantees that the product meets safety regulations and industry standards (UL, CE, FCC, ISO, among others).

When both aspects are developed in parallel, the result is a solid design that minimizes risks and accelerates the path to market.

Early Decisions That Make the Difference

It’s not the same to discover compliance issues months into a project as it is to design with compliance in mind from day one. If considered early during the planning stage, compliance becomes part of a company’s development philosophy.

Especially in startups—where young, highly skilled engineers may lack real-world experience—setting compliance and DFM as guiding principles from the start helps prevent projects from stalling.

- Selecting materials and components that are already certified or pre-approved.

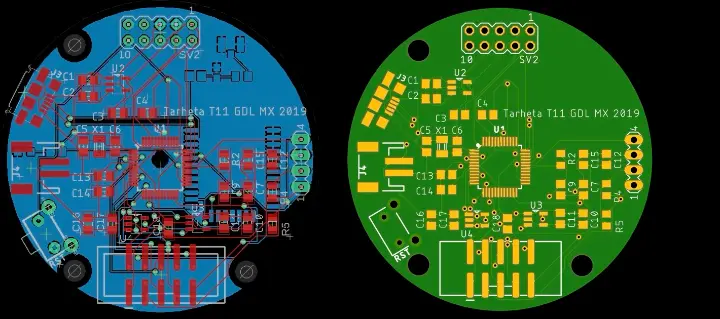

- Designing PCBs that follow clearance and creepage requirements for electrical safety.

- Including labels and warnings that comply with international standards.

- Validating critical components with suppliers experienced in regulated environments.

The Right Structure

Equally important is the team structure—the people who make the magic happen. These individuals not only need strong technical skills, but also a shared focus on achieving the same goal. At a minimum, I recommend the following engineering structure for R&D in a company or startup:

- Electronic Design Team: Hardware, PCBs, BOM selection.

- Firmware Development Team: Algorithms, code, modules, version control.

- Product Design Team: Enclosures, housings in plastic or metal, mechanical assemblies.

- Quality Assurance Team: Standards and compliance validation, test planning, execution.

Of course, there are talented professionals who can take on tasks across multiple areas (and some who claim they can do it all), but having these dedicated teams greatly improves focus, efficiency, and project success.

Benefits of This Integration

- Reduced redesign costs by identifying compliance risks before production.

- Faster time-to-market by avoiding repeated certification cycles.

- Greater investor and customer confidence by ensuring global compliance.

- Competitive advantage: a robust, certified design is more attractive and reliable.

Conclusion

A successful hardware product must not only be functional and aesthetic, but also manufacturable and safe from the start—that is, certifiable. Integrating DFM with regulatory compliance is the way to develop products that reach the market with fewer delays, lower hidden costs, and higher confidence.

If your team needs an engineer with experience in DFM, safety standards, and technology product design, let’s discuss how to accelerate your hardware development.