Coordinate Multiple Suppliers

Working with more than one supplier to manufacture a single product is often unavoidable in complex projects. But when that number grows to 5, 6, or more suppliers per unit, whatever can go wrong… probably will.

In my experience as a Product Leader at a startup —developing a medical device for blind users— and also at Dagaa, where we’ve developed complex products for companies like Bosch and Urrea Tools, as well as mobility and public tech projects, I’ve had to coordinate metal parts manufacturers, PCB fabricators, plastic injection mold makers, final assembly suppliers, and more.

Here’s what I’ve learned to stay in control. You won’t avoid every surprise, but you can be ready for them — and always protect your margins.

1. Map your manufacturing flow from day one

Before your first supplier receives a file, you need a clear visual map of your manufacturing flow:

- Who delivers what, and in what order?

- Which suppliers depend on others?

- Where are idle times likely to accumulate?

Even a simple diagram (on a whiteboard, your iPad, or in Notion) will help you anticipate bottlenecks and define critical validation checkpoints.

2. Document more than you think is necessary

When you work with multiple suppliers, errors usually come from information gaps.

Document clearly:

- Critical tolerances: Your technical drawings must define key dimensions that affect assembly or product function.

- Assembly instructions: You can record them with your phone or use Fusion 360’s animation module. Once they’re ready, upload them to your ERP (Odoo’s manufacturing module supports this in detail).

- Packaging and shipping methods: Don’t overlook packaging — define it from the start when mapping your flow. It often means adding another supplier.

- Clear, confirmed delivery dates: Every quote request should include delivery timelines. Avoid vague commitments.

Each supplier should receive only what they need — but it must be unambiguous.

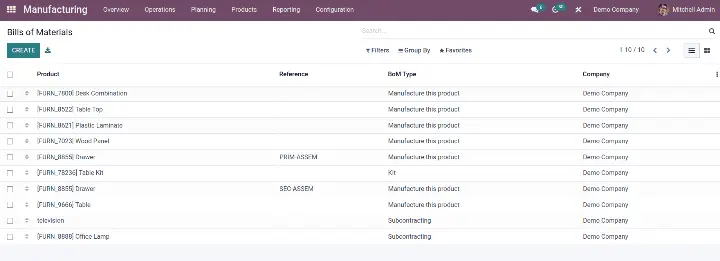

3. Use a system (not disconnected Excel files)

Excel still has its place, but you need a centralized system to track:

- Who’s working on what

- Which parts have been delivered

- What’s still missing

At Dagaa, we use Odoo as our ERP to have full visibility across bill of materials, purchase orders, warehouse control, and interconnected production routes.

Pro tip: You can create virtual warehouses in your ERP for your suppliers’ locations, so you can track material movements even when inventory isn’t physically at your site.

4. Ensure quality without becoming an inspector

Delegating doesn’t mean giving up control. Instead of checking every part yourself, establish:

- Internal quality protocols with each supplier

- Clear visual specifications

- Simple pass/fail acceptance criteria

This should be discussed early in negotiations so that suppliers assign someone responsible for performing quality checks before delivery.

5. Plan for chaos

Even with everything well planned, at least one supplier will get delayed. The key is to:

- Build buffer time between critical stages — I strongly recommend this. Also, using an agile mindset helps: work in milestones, iterate, and stay adaptive.

- Have a backup supplier, when viable. Yes, it may mean extra negotiation and onboarding, but in a crisis, having alternatives gives you options.

- Communicate proactively when the plan changes. Many changes come from clients or upper management. You can’t stop them, but you can be prepared to adapt.

- Don’t let others make unrealistic delivery promises. Clients or managers may commit to fantasy timelines. Don’t allow it — be firm and clear about what can actually be delivered, whether in development stages or finished products.

- Update your kanban boards regularly. Make it part of your routine — daily or twice a week. Use tools like Asana, Monday, Notion, or Odoo’s project module. Give stakeholders access, and make sure they know how to use it.

Your job isn’t to eliminate problems entirely, but to absorb their impact without affecting product quality, timelines, or costs. Always remember: the final product must meet engineering specs, deadlines, and cost targets. (I’ll explore cost analysis in a future blog post.)

Conclusion

Coordinating multiple suppliers isn’t some mystical art, but it’s definitely not something you can improvise. With clear processes, the right tools, proactive communication, and a mindset ready for surprises, you can keep quality, timelines, and margins under control — even across international supply chains.

I’ve personally managed suppliers for the same project in two Asian countries, the U.S., and Mexico… all at the same time.

Want help streamlining your product development workflow — from design to multi-supplier manufacturing?