Most industrial companies —whether in manufacturing, electronics, robotics, construction, or electrical installations— generate an enormous amount of information every day: material purchases, project data, client types, performance results, and delivery times.

Yet most of that data remains unused.

Machine Learning (ML) can transform that information into predictive models that anticipate results and support better strategic decisions.

From Historical Data to Predictions

Imagine a company that has been tracking its operations for years:

- Material purchases,

- Project types,

- Client profiles,

- Outcomes (won or lost),

- And, for the projects that were won, whether they were profitable, delivered on time, and completed within the estimated effort.

If properly structured, this data can feed a model capable of identifying patterns and predicting future outcomes, such as:

- The probability of winning a new quote,

- The expected profitability of a project,

- Potential cost or schedule deviations,

- And the factors that most influence success or failure.

When combined with other datasets —like employee attendance, team participation, weather conditions, material price fluctuations, or economic and political variables— the model can capture more complex relationships and offer sharper predictions.

What Kind of Models Can Be Built

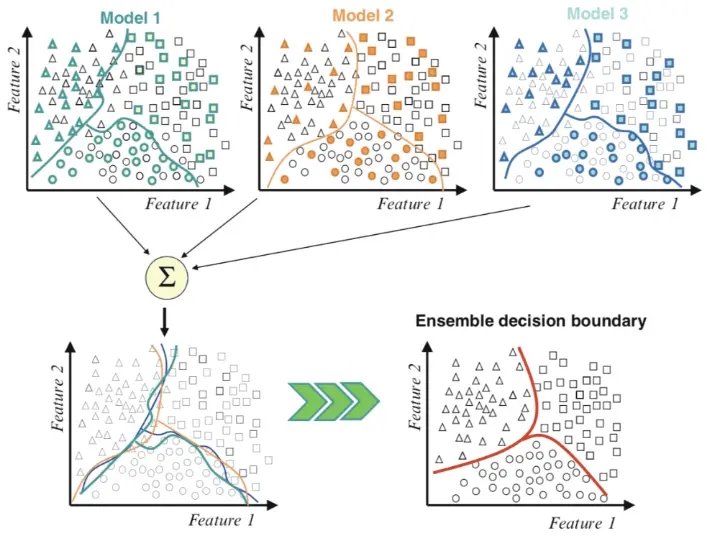

Depending on the business goal, different types of predictive models can be applied:

- Classification models to estimate whether a new opportunity has a high or low chance of being won.

- A classic example is the “Win Propensity” model, used in sales pipelines to predict the likelihood of winning a business opportunity (Sales Pipeline Win Propensity Prediction: A Regression Approach, arXiv, 2015).

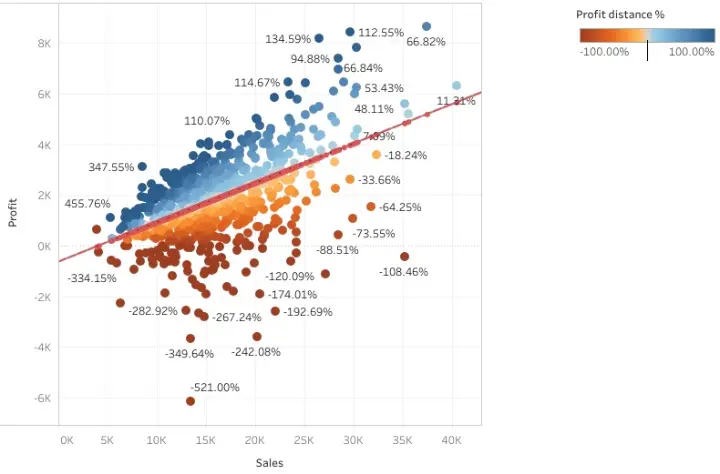

- Regression models to estimate continuous outcomes such as profitability, expected delays, or cost overruns.

- Risk or anomaly detection models to anticipate significant deviations in material consumption, timing, or labor hours.

- Explanatory models to understand why certain projects outperform others, identifying which variables weigh most on final results.

The Heart of Predictive Models: Feature Engineering

A critical part of the process is Feature Engineering —the practice of transforming raw data into meaningful inputs for a model.

It’s not about having more data; it’s about using it intelligently.

Feature engineering involves:

- Creating new variables from existing ones,

- Scaling or normalizing data,

- Detecting correlations,

- And selecting only the variables that truly add value to the prediction.

As highlighted in Machine Learning and Predictive Modeling – Mashkraft, effective feature engineering often determines whether a model becomes a business tool or just an academic exercise.

Data Quality, Context, and Continuity

-

Data Quality

A model is only as good as the data behind it. Cleaning, deduplication, and consistent structure are essential. -

Business Context

The variables must make sense in relation to the company’s operations. The data that drives an industrial electrical project is not the same as what drives a robotics prototype or a construction site. -

Model Continuity

Markets evolve. Material prices, technologies, labor costs, and regulations change. Predictive models must be refreshed periodically to stay accurate and relevant.

From Prediction to Action

Predictive modeling isn’t just about building algorithms —it’s about embedding insights into daily decisions.

Practical applications include:

- Prioritizing quotes with a higher probability of success.

- Detecting projects likely to drift off schedule or budget.

- Identifying human or logistical factors that most affect profitability.

- Optimizing purchasing and resource planning based on historical behavior.

In short: the goal isn’t to predict out of curiosity, but to anticipate in order to act.

Why This Approach Matters

In a competitive environment, companies that can translate their data into predictive intelligence gain a clear advantage.

They reduce uncertainty, manage risk proactively, and deploy resources more efficiently.

What’s most interesting is that many already have all the necessary data —they just need to structure it and approach it with the right analytical mindset.

Conclusion

Machine Learning isn’t reserved for tech giants.

Any company that has been recording its operations for a few years can use its own data to learn, adapt, and project future performance.

Predictive models help organizations make clearer decisions, foresee challenges, and strengthen profitability.

Most organizations already possess the information they need —what they lack is a smarter way to read it.

That’s where predictive models become a design tool: they reveal how decisions, teams, materials, and context interact to form a clearer picture of what’s ahead.

At Dagaa, we develop models that do exactly that —turning data into actionable insight by combining technical understanding with business perspective.

Every model is unique, because every company has its own pattern, its own rhythm, and its own story written in data.

Sometimes, the first step isn’t to predict the future —it’s simply to start seeing it more clearly.